The Queensland drought situation is ever changing. You’ve come to the right place to find practical information to help you manage your way through dry seasons.

Primary producers can adopt many different risk management strategies to minimise the impacts of drought.

Your best bet is to be informed of what support, tools and information is available.

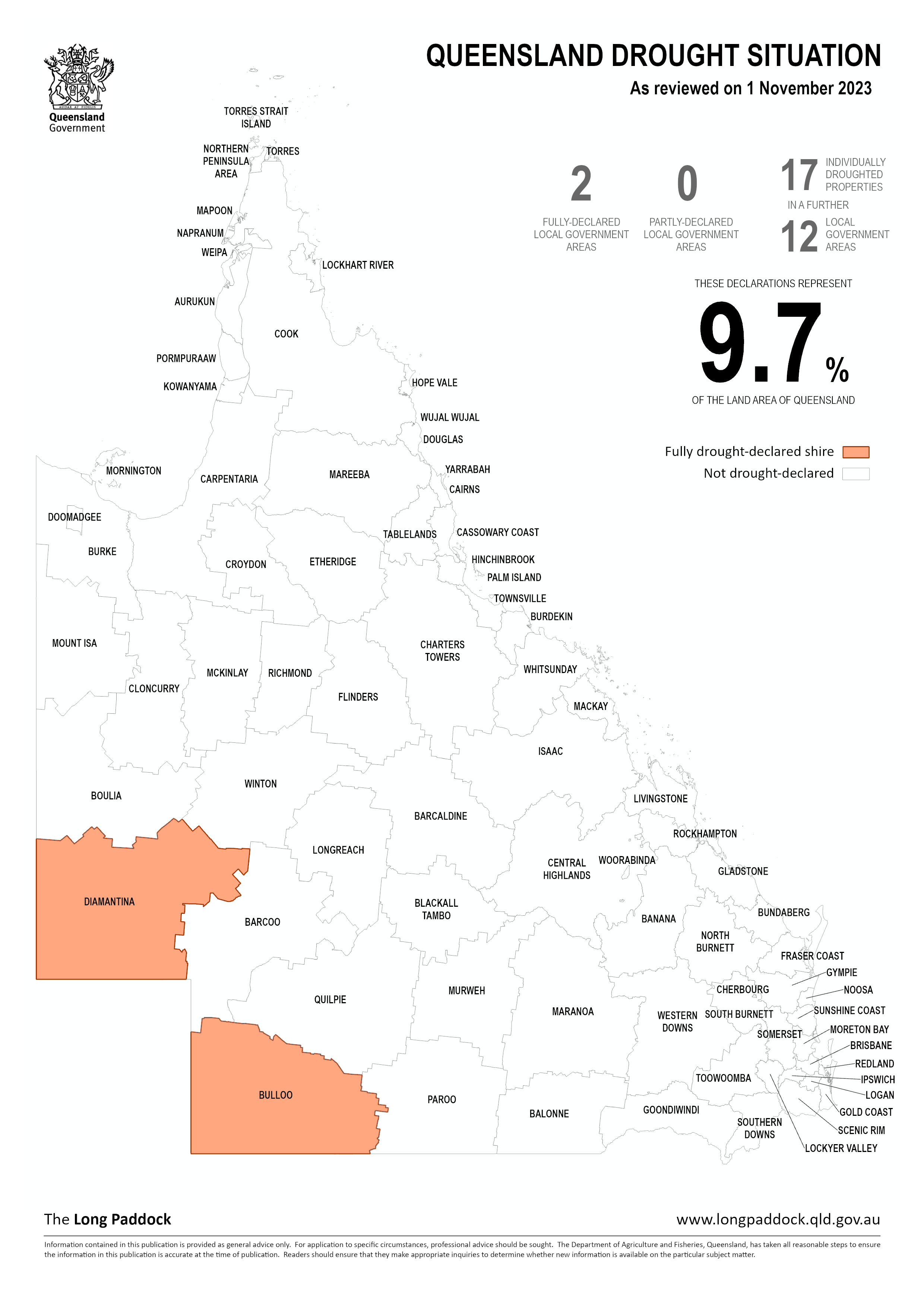

Above shows the current map of the drought declared shires in Queensland (from The Long Paddock website). The areas that are shaded represent those that are fully drought declared up to the date displayed. It also calculates the total area within QLD that is fully drought declared and has statistics of individual drought declared properties.